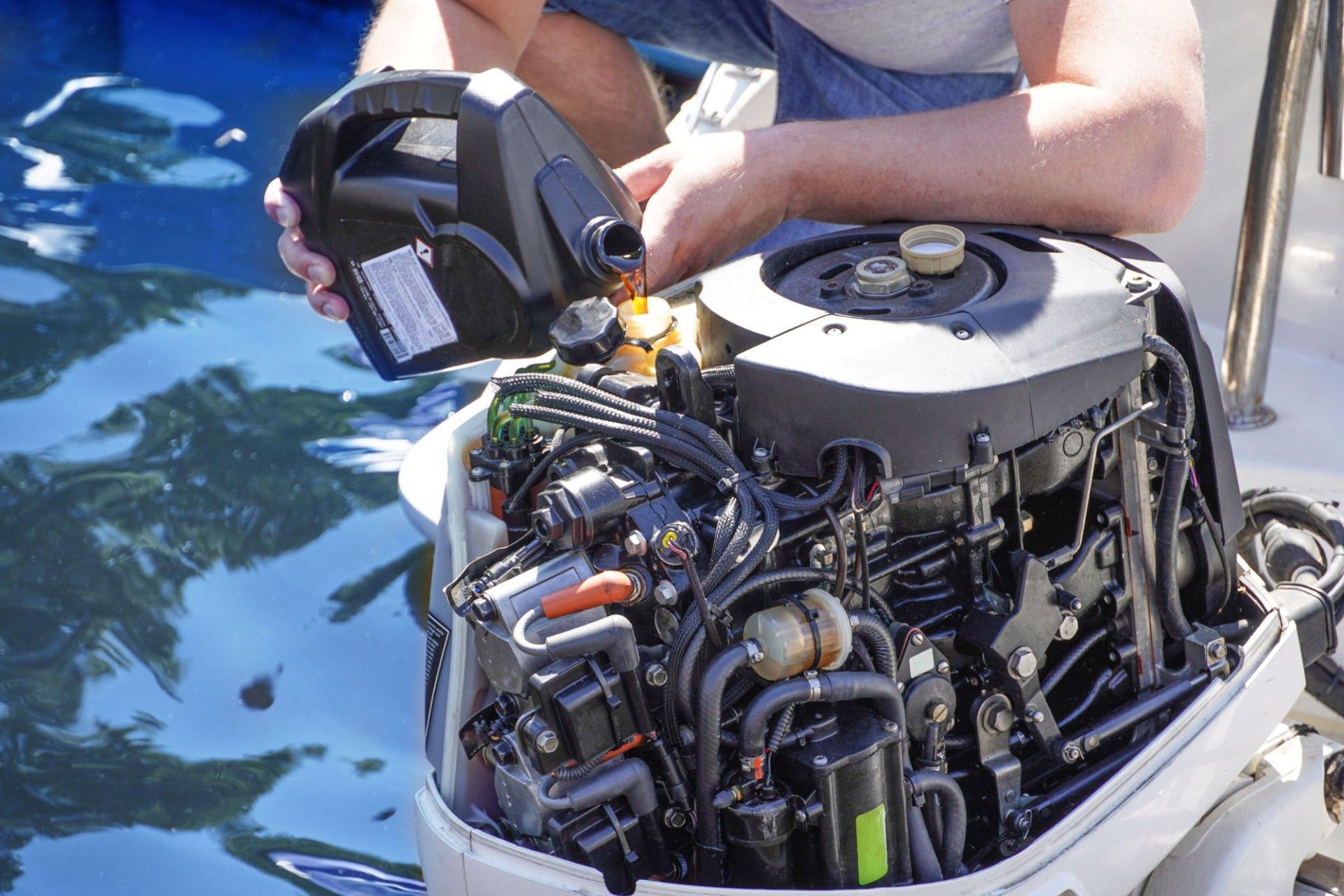

How to Do Fiberglass Repair Like A Pro

Fiberglass is a versatile and durable material used in a wide range of applications, from boats and automobiles to household fixtures and outdoor equipment. Over time, even the toughest fiberglass surfaces can suffer wear and tear, leading to cracks, chips, or other forms of damage. The good news is that with the right knowledge and techniques, you can learn how to do fiberglass repair like a pro. In this comprehensive guide, we'll take you through the steps and

tips for fiberglass boat repair to restore fiberglass surfaces to their former glory.

Step 1: Gather Your Materials

Before you start any repair project, it's essential to gather all the necessary materials and tools. Here's a list of what you'll need:

Safety Gear

Safety should be your top priority. Wear protective gear, including safety glasses, gloves, and a dust mask, to keep yourself safe from fiberglass particles.

Fiberglass Repair Kit

Purchase a fiberglass repair kit, which typically includes resin, hardener, fiberglass cloth, mixing containers, and applicators.

Sandpaper

You'll need various grits of sandpaper (from coarse to fine) to smooth the repaired area.

Sanding Block

A sanding block helps you achieve a flat and even surface.

Clean Cloth or Paper Towels

These are essential for cleaning and wiping down surfaces during the repair process.

Painter's Tape

Use painter's tape to mask off areas you don't want to be repaired or painted.

Wax Paper

This can be used to smooth out the fiberglass cloth and prevent it from sticking to your hands.

Step 2: Prepare the Damaged Area

Before you can begin repairing fiberglass, you need to prepare the damaged area. Here's what you should do:

Safety First

Put on your safety gear to protect yourself from fiberglass dust and fumes.

Clean the Area

Remove any dirt, debris, or loose fiberglass particles from the damaged area. Use a clean cloth or paper towel and a suitable cleaning solution.

Sand the Area

Gently sand the damaged area with coarse sandpaper to remove any loose or damaged fiberglass. This will also create a rough surface for the repair material to adhere to.

Step 3: Apply the Fiberglass Repair Kit

Mix the Resin and Hardener

Follow the instructions provided with your repair kit to mix the resin and hardener. Typically, you'll use a specific ratio, and you should mix them thoroughly.

Apply the First Layer

Lay the fiberglass cloth over the damaged area and use an applicator to saturate it with the resin mixture. Ensure that the cloth is fully wetted out and pressed firmly against the damaged surface.

Add Additional Layers

Depending on the severity of the damage, you may need to add additional layers of fiberglass cloth and resin. Each layer should be fully saturated and applied before the previous one has dried.

Step 4: Sand and Finish

Wait for Curing

Allow the fiberglass repair to cure according to the instructions on the repair kit. This usually takes a few hours to a day.

Sand Smooth

Once the repair has cured, use progressively finer grits of sandpaper to sand the repaired area until it is smooth and level with the surrounding surface.

Finish and Paint

If necessary, you can apply a gel coat or paint to match the surrounding surface. Follow the manufacturer's instructions for proper application.

Step 5: Final Touches

Clean Up

Dispose of any used materials and clean your tools and workspace thoroughly.

Inspect and Test

After completing the repair, inspect the repaired area carefully. Ensure it's structurally sound and cosmetically satisfactory.

By following these steps and taking your time, you can perform fiberglass repair like a pro. With practice, you'll become more skilled and confident in handling fiberglass repair projects, whether they involve a small ding on your boat or a more extensive repair on an automotive component. Remember that safety is paramount throughout the process, so always use appropriate protective gear and follow safety guidelines.

Fiberglass repair can be a cost-effective and sustainable way to extend the life of various objects and surfaces, and with the skills you've gained, you'll be better equipped to tackle future projects with confidence. If the DIY fiberglass repair doesn't work for you,

contact CV Composites Boat Repair immediately. We have the best team to deliver quality

fiberglass repair in Florida.